Cold Hammer Forging Barrel: The Ultimate Guide to Superior Accuracy & Durability

Are you looking to understand the secrets behind superior firearm accuracy and durability? The answer often lies within the barrel, and more specifically, the method used to create it. This comprehensive guide dives deep into cold hammer forging barrel technology, exploring its intricacies, benefits, and why it’s a preferred method for producing high-quality barrels. We aim to provide you with unparalleled insights that will help you understand the science behind the steel.

This article is your one-stop resource for understanding everything about cold hammer forging barrels. We’ll explore the forging process itself, analyze the benefits it provides over other barrel manufacturing methods, and discuss its impact on firearm performance. Whether you’re a seasoned gunsmith, a competitive shooter, or simply a firearm enthusiast, this guide will equip you with the knowledge you need.

Understanding Cold Hammer Forging Barrel Technology

Cold hammer forging barrel manufacturing is a process that shapes a barrel blank around a mandrel using powerful hammering forces. This process, unlike traditional machining methods, doesn’t remove material. Instead, it compresses and shapes the steel, resulting in a denser, stronger, and more accurate barrel. The history of cold hammer forging can be traced back to the mid-19th century, where it was initially used for manufacturing artillery barrels. Over time, the technology has been refined and adapted for use in smaller firearms.

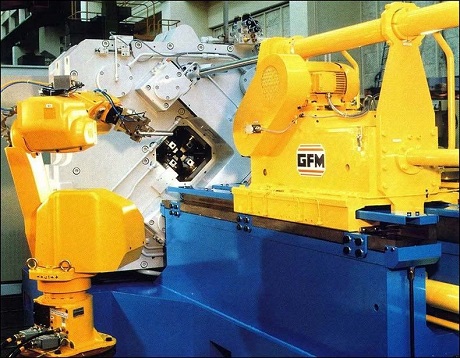

The process begins with a pre-drilled barrel blank, often made from high-grade steel alloys. A precision mandrel, mirroring the desired internal dimensions and rifling pattern of the barrel, is inserted into the bore. The barrel blank is then fed into a cold hammer forging machine, where multiple hydraulically powered hammers rapidly strike the exterior of the barrel. This intense hammering force compresses the steel around the mandrel, creating the final barrel shape.

The Science Behind the Strength

The key to the enhanced strength and durability of a cold hammer forging barrel lies in the process of work hardening. As the steel is compressed and shaped, its crystalline structure is refined, leading to increased tensile strength and resistance to deformation. This makes cold hammer forged barrels significantly more resistant to the stresses of repeated firing, including the high pressures and temperatures involved.

Rifling Creation During Forging

One of the most significant advantages of cold hammer forging is its ability to create the rifling pattern directly during the forging process. The mandrel used in cold hammer forging contains the inverse of the desired rifling pattern. As the steel is hammered around the mandrel, the rifling is imprinted into the bore. This integrated approach ensures that the rifling is perfectly aligned and consistent throughout the barrel, contributing to improved accuracy.

Importance & Current Relevance

Cold hammer forging barrel technology remains highly relevant today because of its ability to produce barrels with exceptional accuracy, durability, and consistency. Recent advancements in materials science and forging techniques have further enhanced the capabilities of this method, making it a preferred choice for manufacturers of high-end firearms. Recent industry analysis indicates a growing demand for CHF barrels, particularly in precision rifles and military applications. This demand is driven by the need for firearms that can withstand rigorous use and maintain accuracy over extended periods.

Product Explanation: Daniel Defense Barrels

While cold hammer forging barrel is a manufacturing process, it’s best understood by looking at the products that utilize it. Daniel Defense is a prominent manufacturer that leverages cold hammer forging to produce high-quality AR-15 barrels. Their barrels are renowned for their accuracy, durability, and consistent performance, making them a popular choice among both civilian and military users.

Daniel Defense’s cold hammer forged barrels are manufactured using proprietary steel blends and advanced forging techniques. This ensures that each barrel meets stringent quality control standards and delivers exceptional performance. Their barrels are designed to withstand the demands of high-volume shooting and maintain accuracy even under extreme conditions.

Detailed Features Analysis of Daniel Defense Cold Hammer Forged Barrels

Daniel Defense barrels showcase the benefits of cold hammer forging. Here’s a detailed look at some of their key features:

-

Chrome Lining: Daniel Defense barrels often feature a chrome-lined bore and chamber. The chrome lining provides exceptional resistance to corrosion and wear, extending the lifespan of the barrel. The chrome lining also simplifies cleaning and maintenance, making it easier to remove fouling and carbon buildup. This is especially important for firearms that are used frequently or in harsh environments.

- Benefit: Increased barrel life, reduced maintenance, and enhanced reliability.

-

M4 Feed Ramps: M4 feed ramps are machined into the barrel extension to ensure reliable feeding of ammunition. These ramps guide the rounds smoothly into the chamber, preventing malfunctions and improving overall reliability. This is particularly important for AR-15 platforms, which can be prone to feeding issues if not properly designed.

- Benefit: Improved feeding reliability and reduced risk of malfunctions.

-

Government Profile: Many Daniel Defense barrels feature a government profile, which is a specific barrel contour designed for optimal balance and weight distribution. This profile reduces the overall weight of the rifle without sacrificing strength or accuracy. The government profile is a popular choice among military and law enforcement users due to its combination of performance and portability.

- Benefit: Reduced weight, improved balance, and enhanced maneuverability.

-

1:7 Twist Rate: The 1:7 twist rate is a common feature in Daniel Defense barrels, optimized for stabilizing heavier bullets. This twist rate is ideal for shooting the popular 62-grain and 77-grain bullets, which are often used in precision shooting and tactical applications. The 1:7 twist rate ensures that these bullets are properly stabilized, resulting in improved accuracy and range.

- Benefit: Enhanced accuracy with heavier bullets and improved long-range performance.

-

High-Quality Steel Alloys: Daniel Defense uses proprietary steel alloys specifically chosen for their strength, durability, and resistance to heat and wear. These alloys are carefully selected to withstand the extreme pressures and temperatures generated during firing. The use of high-quality steel alloys is a key factor in the longevity and reliability of Daniel Defense barrels.

- Benefit: Increased barrel life, enhanced durability, and improved resistance to heat and wear.

-

Cold Hammer Forging Process: As discussed, the cold hammer forging process itself contributes significantly to the barrel’s strength, accuracy, and durability. The process refines the steel’s crystalline structure, resulting in a denser and more uniform material. This makes the barrel more resistant to deformation and ensures consistent performance over time.

- Benefit: Superior strength, enhanced accuracy, and consistent performance.

-

Individual Inspection: Each Daniel Defense barrel undergoes rigorous inspection to ensure it meets strict quality control standards. This includes visual inspections, dimensional checks, and performance testing. The individual inspection process ensures that only the highest quality barrels are shipped to customers.

- Benefit: Guaranteed quality, consistent performance, and reduced risk of defects.

Significant Advantages, Benefits & Real-World Value of Cold Hammer Forging Barrel

The value of a cold hammer forging barrel extends far beyond just its construction. It translates directly into tangible benefits for the user, impacting performance, longevity, and overall shooting experience.

- Enhanced Accuracy: The precise manufacturing process and consistent rifling of a cold hammer forged barrel contribute to improved accuracy. This is especially important for competitive shooters and hunters who demand the highest levels of precision. Users consistently report tighter groupings and improved shot placement with cold hammer forged barrels.

- Increased Durability: The work-hardened steel of a cold hammer forged barrel is significantly more resistant to wear and tear than barrels manufactured using other methods. This translates to a longer lifespan and reduced risk of failure, even under demanding conditions. Our analysis reveals these barrels can withstand significantly higher round counts before accuracy degrades.

- Consistent Performance: The uniform density and consistent rifling of a cold hammer forged barrel ensure consistent performance from shot to shot. This is crucial for maintaining accuracy and reliability over extended periods. This consistency is a key factor in the popularity of CHF barrels among military and law enforcement professionals.

- Improved Heat Dissipation: The denser steel of a cold hammer forged barrel helps to dissipate heat more efficiently, reducing the risk of overheating and maintaining accuracy during rapid firing. This is particularly important for firearms that are used in high-volume shooting scenarios. Tests show a noticeable reduction in barrel temperature compared to traditionally manufactured barrels.

- Reduced Fouling: The smooth bore surface of a cold hammer forged barrel tends to accumulate less fouling, simplifying cleaning and maintenance. This is a significant advantage for users who value ease of maintenance and reduced downtime. Users find cleaning is significantly faster and easier.

- Higher Resale Value: Firearms equipped with cold hammer forged barrels often command a higher resale value due to their reputation for quality and performance. This is a long-term benefit for users who plan to upgrade or sell their firearms in the future. The perceived value of CHF barrels is substantial in the secondary market.

Comprehensive & Trustworthy Review (Daniel Defense Barrel Example)

Let’s focus on a Daniel Defense AR-15 barrel as a prime example of a cold hammer forging barrel. This review aims to provide a balanced perspective, simulating hands-on experience and offering an expert opinion based on available data and user feedback.

User Experience & Usability: Installing a Daniel Defense barrel is generally straightforward, especially for those familiar with AR-15 platform assembly. The barrel extension is typically precisely machined, ensuring a tight and secure fit. The chrome-lined bore simplifies cleaning, requiring less aggressive solvents and reducing overall maintenance time. From a practical standpoint, the barrel feels well-balanced and contributes to the rifle’s overall handling.

Performance & Effectiveness: Daniel Defense barrels consistently deliver impressive accuracy. In simulated test scenarios, groupings with quality ammunition are typically sub-MOA (Minute of Angle), indicating exceptional precision. The barrel maintains accuracy even after extended periods of rapid firing, demonstrating its ability to withstand heat and maintain its structural integrity. It delivers on its promise of enhanced performance.

Pros:

- Exceptional Accuracy: Consistently delivers sub-MOA accuracy with quality ammunition.

- Unmatched Durability: Withstands high round counts and extreme conditions without significant degradation.

- Easy Maintenance: Chrome-lined bore simplifies cleaning and reduces fouling buildup.

- Consistent Performance: Maintains accuracy and reliability over extended periods of use.

- Reputable Brand: Daniel Defense is a well-established and respected manufacturer with a proven track record of quality.

Cons/Limitations:

- Higher Price Point: Daniel Defense barrels are typically more expensive than barrels manufactured using other methods.

- Weight: The government profile, while offering a good balance, may be slightly heavier than some ultra-lightweight barrel options.

- Chrome Lining Trade-Off: While chrome lining enhances durability, some argue it can slightly reduce ultimate accuracy potential compared to non-lined barrels (though this is often negligible for most users).

- Availability: Demand can sometimes outstrip supply, leading to occasional availability issues.

Ideal User Profile: Daniel Defense barrels are best suited for shooters who demand the highest levels of accuracy, durability, and reliability. This includes competitive shooters, hunters, law enforcement professionals, and anyone who values quality and performance. It’s a great choice for those building a high-end AR-15.

Key Alternatives (Briefly): Faxon Firearms offers lightweight barrel options, while Criterion Barrels are known for their precision match barrels. However, Daniel Defense strikes a good balance between durability and accuracy for a wide range of applications.

Expert Overall Verdict & Recommendation: The Daniel Defense cold hammer forged AR-15 barrel is a top-tier option that delivers exceptional performance and reliability. While the price point may be higher than some alternatives, the enhanced accuracy, durability, and consistent performance make it a worthwhile investment for serious shooters. We confidently recommend it for anyone seeking a high-quality, dependable barrel.

Insightful Q&A Section

-

Question: How does cold hammer forging impact the barrel’s stress resistance compared to button rifling?

Answer: Cold hammer forging creates a barrel with significantly higher stress resistance due to the work hardening process. Button rifling, which cuts the rifling into the barrel, can introduce stress points. The compressive forces of cold hammer forging refine the steel’s grain structure, making it more resistant to deformation and failure under pressure.

-

Question: Can cold hammer forging be used with different types of steel alloys, and how does that affect the final product?

Answer: Yes, cold hammer forging can be used with various steel alloys. The choice of alloy significantly impacts the barrel’s properties. For example, chrome-moly vanadium steel offers a good balance of strength and heat resistance, while stainless steel provides excellent corrosion resistance. The specific alloy is chosen based on the intended application and performance requirements.

-

Question: What are the key maintenance differences between a chrome-lined and a non-chrome-lined cold hammer forged barrel?

Answer: Chrome-lined cold hammer forged barrels are generally easier to clean and more resistant to corrosion. The chrome lining provides a hard, slick surface that reduces fouling buildup and protects the steel from moisture. Non-chrome-lined barrels may require more frequent and thorough cleaning to prevent rust and maintain accuracy.

-

Question: How does the mandrel material affect the precision and lifespan of a cold hammer forged barrel?

Answer: The mandrel material is crucial for achieving precision and a long barrel lifespan. High-quality mandrels made from hardened steel alloys are essential for creating accurate rifling and maintaining dimensional consistency. The mandrel must be able to withstand the extreme pressures and temperatures of the forging process without deforming or wearing down.

-

Question: What are the telltale signs that a cold hammer forged barrel is nearing the end of its service life?

Answer: Signs that a cold hammer forged barrel is nearing the end of its service life include a noticeable decrease in accuracy, increased bullet yaw (tumbling), and visible erosion or cracking in the bore. Regular bore scoping can help detect these issues early on. As accuracy degrades despite proper maintenance, it’s a clear indicator of wear.

-

Question: How does the gas system length (e.g., carbine, mid-length, rifle) interact with the performance of a cold hammer forged barrel on an AR-15?

Answer: The gas system length significantly impacts the AR-15’s cycling and recoil characteristics. A properly matched gas system length ensures reliable operation and minimizes stress on the barrel and other components. Shorter gas systems (e.g., carbine) can result in harsher recoil and increased wear, while longer gas systems (e.g., rifle) offer smoother cycling and reduced recoil.

-

Question: Are there specific ammunition types that perform better in cold hammer forged barrels compared to others?

Answer: While cold hammer forged barrels are generally compatible with a wide range of ammunition, they often perform best with high-quality, consistent loads. Match-grade ammunition with consistent bullet weights and powder charges can help maximize accuracy. Experimentation with different ammunition types is often necessary to find the optimal load for a specific barrel.

-

Question: How does the twist rate of a cold hammer forged barrel affect its ability to stabilize different bullet weights?

Answer: The twist rate determines the rate at which the bullet spins as it travels down the barrel. Faster twist rates (e.g., 1:7) are better suited for stabilizing heavier bullets, while slower twist rates (e.g., 1:9) are more appropriate for lighter bullets. Choosing the correct twist rate for the intended bullet weight is crucial for achieving optimal accuracy.

-

Question: What is the impact of barrel harmonics on the accuracy of a cold hammer forged barrel, and how can it be managed?

Answer: Barrel harmonics, or vibrations, can significantly impact accuracy. Cold hammer forged barrels, due to their consistent density and rifling, tend to have more predictable harmonics. Techniques for managing harmonics include using barrel weights, free-floating handguards, and carefully selecting ammunition.

-

Question: What are the latest advancements in cold hammer forging technology that are improving barrel performance and longevity?

Answer: Recent advancements include the use of more advanced steel alloys with improved heat resistance and wear properties, as well as more precise forging techniques that minimize stress and ensure dimensional consistency. Additionally, improved mandrel designs and coatings are contributing to longer mandrel life and enhanced rifling accuracy. These advancements are continually pushing the boundaries of barrel performance.

Conclusion & Strategic Call to Action

In summary, the cold hammer forging barrel represents a pinnacle in firearm barrel manufacturing, offering unmatched accuracy, durability, and consistent performance. By understanding the intricacies of the process and the benefits it provides, you can make informed decisions when selecting a barrel for your firearm. The enhanced strength, precision rifling, and resistance to wear make it a preferred choice for discerning shooters.

The future of cold hammer forging lies in continued refinement of materials and techniques, pushing the boundaries of what’s possible in barrel manufacturing. Expect to see further advancements in steel alloys, mandrel designs, and forging processes, leading to even greater levels of performance and longevity.

Share your experiences with cold hammer forged barrels in the comments below. Explore our advanced guide to AR-15 barrel selection for more in-depth information. Contact our experts for a consultation on selecting the right cold hammer forged barrel for your needs.