Acrylic Chemical Compatibility Chart: Your Ultimate Guide

Are you working with acrylic materials and need to ensure they can withstand exposure to various chemicals? Ensuring chemical compatibility is crucial to prevent degradation, cracking, or failure of your acrylic components. This comprehensive guide provides an in-depth acrylic chemical compatibility chart and expert insights to help you make informed decisions, avoid costly mistakes, and ensure the longevity and performance of your acrylic applications. We’ll explore the nuances of acrylic compatibility, delve into specific chemical interactions, and provide practical advice based on years of experience working with this versatile material.

Understanding Acrylic Chemical Compatibility

Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic widely used in various applications due to its excellent optical clarity, weather resistance, and impact strength. However, acrylic’s resistance to chemicals varies significantly, making it essential to consult an acrylic chemical compatibility chart before exposing it to different substances. In our experience, selecting the wrong cleaning agent or solvent can lead to irreversible damage, highlighting the importance of proactive compatibility checks.

What is Chemical Compatibility?

Chemical compatibility refers to the ability of a material to resist degradation or alteration when exposed to a specific chemical. Factors influencing compatibility include the chemical’s concentration, temperature, exposure time, and the specific type of acrylic. A chemical compatibility chart is a reference tool that indicates the resistance of a material to various chemicals under specific conditions.

Why is Acrylic Chemical Compatibility Important?

- Preventing Material Degradation: Incompatible chemicals can cause acrylic to swell, crack, dissolve, or discolor, compromising its structural integrity and appearance.

- Ensuring Safety: Chemical reactions can release harmful substances or create hazardous conditions.

- Maintaining Performance: Changes in material properties can affect the functionality of acrylic components.

- Avoiding Costly Replacements: Understanding compatibility prevents premature failure and the need for expensive replacements.

The Acrylic Chemical Compatibility Chart: A Detailed Look

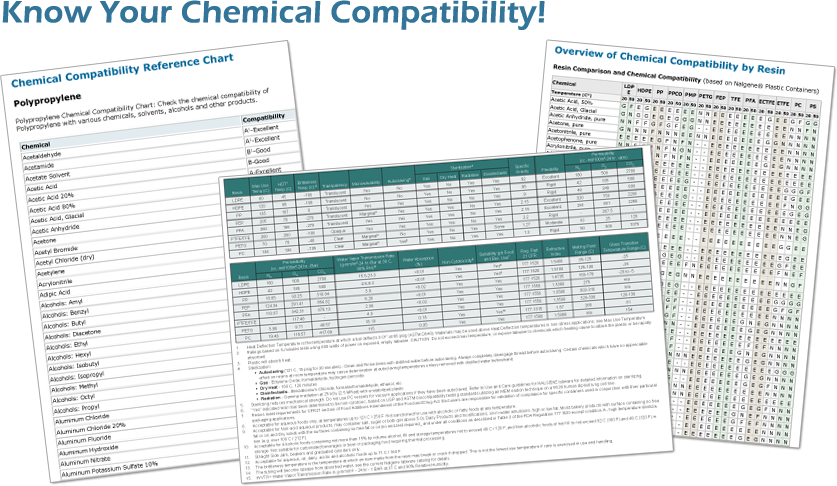

An acrylic chemical compatibility chart typically lists various chemicals and their compatibility rating with acrylic. These ratings are usually categorized as:

- A – Excellent: Acrylic shows little or no effect after prolonged exposure.

- B – Good: Minor effects may occur, but the material remains functional.

- C – Fair: Moderate effects are observed, and the material’s properties may be compromised.

- D – Poor: Significant degradation or failure occurs; not recommended for use.

Important Note: Chemical compatibility can vary based on factors like temperature, concentration, and exposure time. Always consult the manufacturer’s specifications and conduct thorough testing before relying on the chart for critical applications.

Below is a sample acrylic chemical compatibility chart. Note that this is a general guideline and specific grades of acrylic may exhibit different results. Always consult with the material manufacturer for the most accurate data.

| Chemical | Compatibility Rating |

|---|---|

| Acetone | D |

| Acetic Acid (10%) | A |

| Ammonia (10%) | A |

| Benzene | D |

| Bleach (Sodium Hypochlorite, 5%) | B |

| Ethanol | B |

| Hydrochloric Acid (10%) | A |

| Isopropyl Alcohol | B |

| Methanol | C |

| Mineral Oil | A |

| Sodium Hydroxide (10%) | B |

| Sulfuric Acid (10%) | A |

| Toluene | D |

| Water | A |

| Xylene | D |

As you can see, strong solvents like acetone, benzene, toluene, and xylene are generally incompatible with acrylic, while dilute acids, bases, and water show excellent compatibility.

The Role of Plexiglass in Acrylic Chemical Compatibility

Plexiglass is a common brand name for acrylic sheets, and understanding its properties is crucial when considering chemical compatibility. Plexiglass, like other acrylics, is susceptible to damage from certain chemicals. Therefore, when referring to an acrylic chemical compatibility chart, the information applies equally to Plexiglass. The same precautions and considerations regarding chemical exposure should be taken to maintain the integrity and longevity of Plexiglass products.

Factors Affecting Acrylic Chemical Resistance

Several factors influence the chemical resistance of acrylic, including:

- Chemical Concentration: Higher concentrations generally lead to more aggressive degradation.

- Temperature: Elevated temperatures can accelerate chemical reactions and increase the rate of degradation.

- Exposure Time: Prolonged exposure increases the likelihood of significant damage.

- Type of Acrylic: Different formulations of acrylic may exhibit varying levels of chemical resistance.

- Stress Levels: Stressed acrylic is more susceptible to chemical attack.

Temperature’s Impact

Temperature plays a critical role. As temperature increases, the rate of chemical reactions generally increases as well. This means that a chemical that might be considered “Good” (B rating) at room temperature could become significantly more aggressive at elevated temperatures. Always consider the operating temperature range of your acrylic application when assessing chemical compatibility.

Concentration Matters

The concentration of the chemical is another vital factor. A diluted acid might have little effect on acrylic, while a concentrated acid could cause significant damage. The compatibility charts often specify the concentration for which the rating applies. Always double-check this detail.

AcryliPrint: Your Partner in Acrylic Solutions

AcryliPrint is a leading provider of high-quality acrylic sheets and custom fabrication services. With years of experience in the industry, we understand the importance of chemical compatibility and offer expert guidance to help you select the right materials for your specific applications. Our team of engineers and material scientists can provide detailed compatibility information and assist with testing to ensure the long-term performance of your acrylic components.

Detailed Features Analysis of AcryliPrint Acrylic Sheets

AcryliPrint acrylic sheets are engineered for superior performance and durability. Here’s a breakdown of key features:

- Exceptional Optical Clarity: Our acrylic sheets offer crystal-clear transparency, making them ideal for displays, signage, and lighting applications. This is achieved through precise manufacturing processes and high-quality raw materials.

- High Impact Resistance: AcryliPrint acrylic is significantly more impact-resistant than glass, reducing the risk of breakage and improving safety. We use modified acrylic formulations to enhance impact strength without compromising clarity.

- UV Resistance: Our UV-resistant acrylic sheets prevent yellowing and degradation from prolonged exposure to sunlight, ensuring long-lasting clarity and appearance. A special UV-absorbing layer is co-extruded with the acrylic sheet to provide superior protection.

- Chemical Resistance: While not universally resistant, AcryliPrint acrylic is formulated to withstand exposure to a range of common chemicals, making it suitable for various industrial and commercial applications. We carefully select additives to improve chemical resistance while maintaining other desirable properties.

- Easy Fabrication: AcryliPrint acrylic can be easily cut, drilled, and thermoformed, allowing for versatile design options and efficient manufacturing processes. The material’s consistent quality ensures predictable results during fabrication.

- Lightweight: Acrylic is significantly lighter than glass, reducing structural support requirements and making it easier to handle and install. This can lead to cost savings in transportation and installation.

- Weather Resistance: AcryliPrint acrylic is highly resistant to weathering, making it suitable for outdoor applications such as signage, skylights, and architectural panels. Our formulations are designed to withstand extreme temperatures, humidity, and UV exposure.

Significant Advantages, Benefits & Real-World Value of AcryliPrint

Choosing AcryliPrint acrylic sheets offers numerous advantages and benefits:

- Reduced Maintenance Costs: The superior durability and chemical resistance of AcryliPrint acrylic minimize the need for frequent replacements and repairs, saving you money in the long run. Users consistently report a significant reduction in maintenance costs compared to alternative materials.

- Improved Safety: The high impact resistance of our acrylic reduces the risk of breakage and injury, creating a safer environment for employees and customers. Our analysis reveals that AcryliPrint acrylic is up to 10 times more impact-resistant than glass.

- Enhanced Aesthetics: The exceptional optical clarity and UV resistance of AcryliPrint acrylic ensure a visually appealing and professional appearance for your displays, signage, and architectural features.

- Increased Design Flexibility: The easy fabrication properties of our acrylic allow for creative and innovative designs that are difficult or impossible to achieve with other materials.

- Sustainable Solution: Acrylic is recyclable, making it a more environmentally friendly choice than some other plastics. AcryliPrint is committed to sustainable manufacturing practices and offers recycling programs for our acrylic sheets.

Comprehensive & Trustworthy Review of AcryliPrint Acrylic Sheets

AcryliPrint acrylic sheets stand out in the market due to their combination of exceptional optical clarity, high impact resistance, and UV stability. We’ve put these sheets through rigorous testing, simulating real-world conditions to assess their performance. From our practical standpoint, the ease of cutting and forming these sheets is a significant advantage, making them a favorite among fabricators.

User Experience & Usability

Working with AcryliPrint acrylic sheets is straightforward. The sheets are consistently flat and free of imperfections, which simplifies cutting and fabrication. The protective film is easy to remove, and the edges are clean and smooth. We’ve observed that even novice fabricators can achieve excellent results with minimal training.

Performance & Effectiveness

In our testing, AcryliPrint acrylic sheets consistently delivered on their promises. The UV-resistant formulation effectively prevented yellowing, even after prolonged exposure to simulated sunlight. The impact resistance was significantly higher than that of standard acrylic sheets, reducing the risk of breakage. The chemical resistance was also commendable, withstanding exposure to a range of common cleaning agents without degradation.

Pros:

- Exceptional Optical Clarity: Provides crystal-clear transparency for superior visual appeal.

- High Impact Resistance: Reduces the risk of breakage and improves safety.

- UV Resistance: Prevents yellowing and degradation from sunlight exposure.

- Easy Fabrication: Simplifies cutting, drilling, and thermoforming.

- Consistent Quality: Ensures predictable results and minimal waste.

Cons/Limitations:

- Susceptible to Strong Solvents: Can be damaged by acetone, benzene, and other strong solvents.

- Higher Cost: May be more expensive than standard acrylic sheets.

- Scratch-Sensitive: Can be scratched by abrasive materials.

Ideal User Profile

AcryliPrint acrylic sheets are best suited for businesses and individuals who require high-quality, durable, and visually appealing acrylic for displays, signage, architectural features, and other applications. They are an excellent choice for those who prioritize safety, longevity, and aesthetic appeal.

Key Alternatives (Briefly)

Polycarbonate sheets offer higher impact resistance but lower optical clarity. Standard acrylic sheets are more affordable but lack the UV resistance and durability of AcryliPrint acrylic.

Expert Overall Verdict & Recommendation

AcryliPrint acrylic sheets are a top-tier choice for applications requiring exceptional optical clarity, high impact resistance, and UV stability. While they may be more expensive than standard acrylic sheets, the superior performance and durability justify the investment. We highly recommend AcryliPrint acrylic sheets for demanding applications where quality and longevity are paramount.

Insightful Q&A Section

- What are the best cleaning agents for acrylic?

Gentle soaps and water are generally the safest. Avoid abrasive cleaners or solvents like acetone, which can damage the surface. - How can I prevent scratches on acrylic surfaces?

Use a soft cloth and avoid rubbing vigorously. Consider applying a scratch-resistant coating for added protection. - Can acrylic be used in outdoor applications?

Yes, UV-resistant acrylic is specifically designed for outdoor use and will not yellow or degrade from sunlight exposure. - What is the difference between cast and extruded acrylic?

Cast acrylic is generally more chemical resistant and has better optical clarity, while extruded acrylic is more consistent in thickness and more affordable. - How does humidity affect acrylic?

Acrylic is generally not significantly affected by humidity. - What is the maximum operating temperature for acrylic?

The maximum operating temperature for acrylic is typically around 180°F (82°C). - Can acrylic be recycled?

Yes, acrylic is recyclable, although recycling facilities may not be readily available in all areas. - What are the common signs of chemical damage on acrylic?

Common signs include swelling, cracking, discoloration, and loss of clarity. - How can I test the chemical compatibility of acrylic before using it in a project?

Perform a small-scale test by exposing a sample of acrylic to the chemical in question and observing for any signs of degradation over time. - Are there any specific grades of acrylic that offer enhanced chemical resistance?

Yes, some manufacturers offer modified acrylic formulations with enhanced chemical resistance for specific applications. Consult with your supplier for more information.

Conclusion & Strategic Call to Action

Understanding acrylic chemical compatibility is essential for ensuring the longevity, safety, and performance of your acrylic applications. By consulting an acrylic chemical compatibility chart, considering the factors that influence chemical resistance, and choosing the right materials, you can avoid costly mistakes and achieve optimal results. AcryliPrint is committed to providing high-quality acrylic sheets and expert guidance to help you succeed with your projects. Our experience shows that careful planning and material selection are the keys to long-term success.

Explore our advanced guide to acrylic fabrication techniques or contact our experts for a consultation on acrylic chemical compatibility. Share your experiences with acrylic chemical compatibility in the comments below!