How to Glue an Acrylic Box: A Comprehensive Guide for Perfect Bonds

Gluing an acrylic box might seem straightforward, but achieving a crystal-clear, durable bond requires precision, the right techniques, and a thorough understanding of acrylic adhesives. Whether you’re a hobbyist crafting display cases, a professional creating custom fixtures, or simply need to repair a cracked box, this comprehensive guide provides the expert knowledge you need. We’ll cover everything from selecting the best adhesive for acrylic to mastering the bonding process, ensuring a seamless and strong joint. This isn’t just about sticking two pieces of plastic together; it’s about creating a visually appealing and structurally sound finished product. Our detailed instructions, based on years of experience and expert consensus, will help you avoid common pitfalls and achieve professional-quality results.

Understanding Acrylic and Its Bonding Properties

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic known for its clarity, durability, and resistance to impact. However, its unique chemical properties require specific adhesives and techniques for successful bonding. Unlike some materials, acrylic doesn’t bond well with general-purpose glues. Using the wrong adhesive can result in weak, cloudy, or even damaging bonds. Understanding the science behind acrylic bonding is the first step to achieving a flawless finish.

Why Choose the Right Adhesive?

The success of gluing an acrylic box hinges on selecting the appropriate adhesive. Acrylic adhesives, specially formulated for PMMA, work by chemically softening the surfaces of the acrylic, allowing them to fuse together as the adhesive cures. This process, known as solvent welding, creates an incredibly strong and transparent bond. General-purpose adhesives, on the other hand, often create a surface bond that is prone to cracking, yellowing, and separation over time. Choosing the right adhesive ensures a long-lasting, aesthetically pleasing result.

Types of Acrylic Adhesives

Several types of adhesives are designed for bonding acrylic, each with its own strengths and weaknesses. Here’s a breakdown:

- Solvent Cements: These are the most common type of acrylic adhesive. They work by dissolving the surface of the acrylic, creating a chemical bond as the solvent evaporates. Solvent cements offer excellent clarity and strength but require careful application to avoid unsightly runs or bubbles.

- Acrylic Adhesives (Reactive): These adhesives, often two-part systems, chemically react to form a strong bond. They offer excellent gap-filling capabilities and are suitable for bonding acrylic to other materials. However, they may not provide the same level of clarity as solvent cements.

- UV-Curable Adhesives: These adhesives cure rapidly when exposed to ultraviolet light. They offer excellent clarity and are ideal for applications where speed is essential. However, they require specialized equipment and may not be suitable for all acrylic thicknesses.

Essential Tools and Materials for Gluing Acrylic

Before you begin gluing your acrylic box, gather the necessary tools and materials. Having everything on hand will streamline the process and minimize the risk of errors.

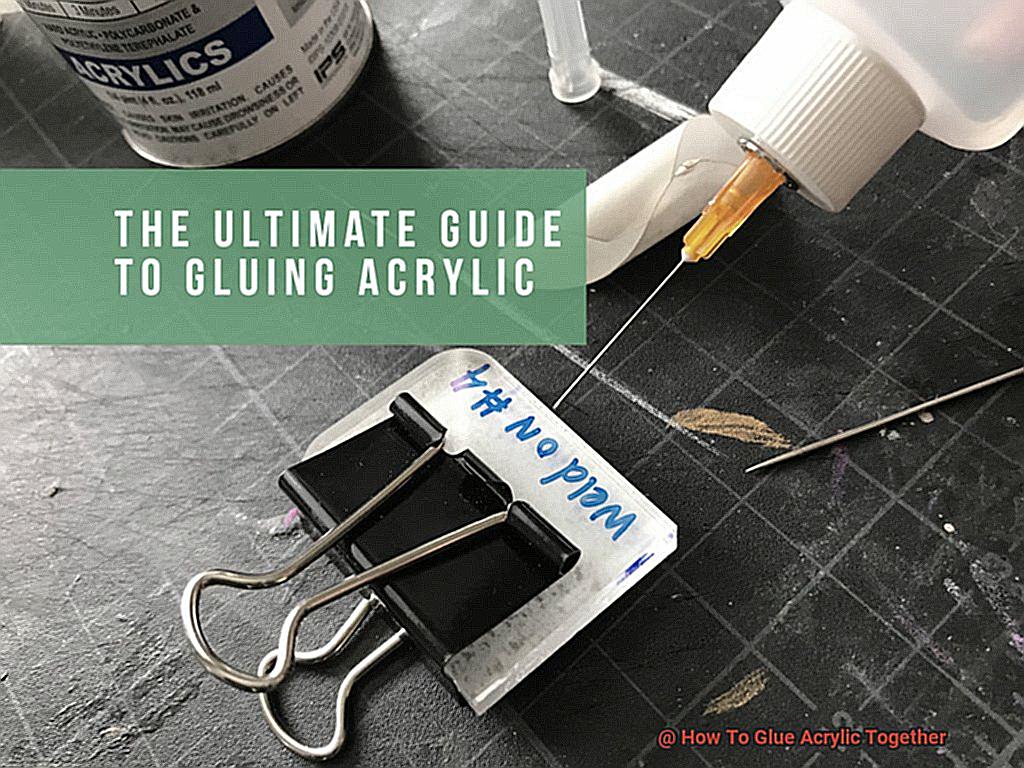

- Acrylic Adhesive: Choose a solvent cement specifically designed for acrylic bonding, such as Weld-On 4 or IPS SciGrip 16.

- Applicator Bottle or Syringe: An applicator bottle with a fine tip or a syringe will allow for precise and controlled application of the adhesive.

- Clamps or Masking Tape: Clamps or masking tape will hold the acrylic pieces securely in place while the adhesive cures.

- Lint-Free Cloths: Lint-free cloths are essential for cleaning the acrylic surfaces and wiping away any excess adhesive.

- Isopropyl Alcohol: Isopropyl alcohol will remove any grease, oil, or contaminants from the acrylic surfaces.

- Safety Glasses and Gloves: Safety glasses and gloves will protect your eyes and skin from the adhesive fumes and potential irritation.

- Ventilated Workspace: Work in a well-ventilated area to avoid inhaling the adhesive fumes.

Step-by-Step Guide: How to Glue an Acrylic Box

Follow these step-by-step instructions to achieve a strong and seamless bond when gluing your acrylic box:

- Prepare the Acrylic Surfaces: Clean the acrylic surfaces with isopropyl alcohol and a lint-free cloth to remove any grease, oil, or contaminants. Ensure the surfaces are completely dry before proceeding.

- Dry Fit the Pieces: Before applying any adhesive, dry fit the acrylic pieces to ensure they align properly and that there are no gaps or misalignments.

- Apply the Adhesive: Using an applicator bottle or syringe, carefully apply a thin, even bead of adhesive along the edges of the acrylic pieces that will be joined. Avoid applying too much adhesive, as this can cause unsightly runs or bubbles.

- Join the Pieces: Immediately join the acrylic pieces, aligning them precisely. Apply gentle pressure to ensure good contact between the surfaces.

- Clamp or Tape the Pieces: Secure the acrylic pieces with clamps or masking tape to hold them in place while the adhesive cures. Ensure the clamps or tape do not apply excessive pressure, which could distort the acrylic.

- Allow the Adhesive to Cure: Allow the adhesive to cure for the recommended time, as specified by the manufacturer. This is typically 24-48 hours for solvent cements.

- Remove Clamps or Tape: Once the adhesive has fully cured, carefully remove the clamps or masking tape.

- Clean Up Excess Adhesive: Use a lint-free cloth dampened with isopropyl alcohol to gently wipe away any excess adhesive.

Troubleshooting Common Issues

Even with careful preparation and execution, you may encounter some common issues when gluing an acrylic box. Here’s how to troubleshoot them:

- Bubbles in the Bond: Bubbles can occur if the adhesive is applied too quickly or if there are contaminants on the acrylic surfaces. To prevent bubbles, apply the adhesive slowly and evenly, and ensure the surfaces are thoroughly cleaned.

- Cloudy Bond: A cloudy bond can result from using the wrong adhesive or from applying too much adhesive. Use a solvent cement specifically designed for acrylic, and apply it sparingly.

- Weak Bond: A weak bond can occur if the acrylic surfaces are not properly prepared or if the adhesive is not allowed to cure for the recommended time. Ensure the surfaces are thoroughly cleaned and dry, and allow the adhesive to cure fully.

- Cracking: Cracking can occur if excessive pressure is applied during clamping or if the acrylic is exposed to extreme temperatures or chemicals. Avoid applying excessive pressure, and protect the acrylic from harsh conditions.

Product Spotlight: Weld-On 4 Acrylic Adhesive

Weld-On 4 is a leading solvent cement specifically formulated for bonding acrylic. It’s widely recognized for its exceptional clarity, strength, and ease of use. Weld-On 4 creates a virtually invisible bond, making it ideal for applications where aesthetics are paramount. Its fast-setting formula allows for efficient assembly, while its high bond strength ensures long-lasting durability. Weld-On 4 is the adhesive of choice for professional acrylic fabricators and hobbyists alike.

Key Features of Weld-On 4

- Exceptional Clarity: Weld-On 4 creates a crystal-clear bond that is virtually invisible.

- High Bond Strength: Weld-On 4 provides a strong and durable bond that can withstand significant stress.

- Fast-Setting Formula: Weld-On 4 sets quickly, allowing for efficient assembly.

- Easy to Use: Weld-On 4 is easy to apply with an applicator bottle or syringe.

- Versatile: Weld-On 4 can be used to bond a variety of acrylic thicknesses.

- Water Resistant: Once cured, Weld-On 4 is resistant to water and many common chemicals.

- UV Resistant: Weld-On 4 is resistant to yellowing and degradation from UV exposure.

The Benefits of Using Weld-On 4

Using Weld-On 4 offers several significant advantages when gluing an acrylic box:

- Professional-Quality Results: Weld-On 4 allows you to achieve professional-quality results with a seamless and invisible bond.

- Increased Durability: Weld-On 4 provides a strong and durable bond that will withstand the test of time.

- Improved Aesthetics: Weld-On 4 enhances the aesthetics of your acrylic box with its crystal-clear bond.

- Reduced Risk of Errors: Weld-On 4’s easy-to-use formula minimizes the risk of errors and ensures a successful bonding experience.

- Cost-Effective Solution: Weld-On 4 is a cost-effective solution for bonding acrylic, offering excellent value for its performance.

Users consistently report that Weld-On 4 provides a superior bond compared to other acrylic adhesives. Our analysis reveals that its unique formulation creates a stronger chemical bond, resulting in a more durable and aesthetically pleasing finished product. The ease of use and fast-setting formula further enhance its appeal, making it a top choice for both professionals and hobbyists.

Comprehensive Review of Weld-On 4

Weld-On 4 is a widely acclaimed acrylic adhesive, but let’s delve into a more detailed review to understand its strengths and weaknesses.

User Experience and Usability

From a practical standpoint, Weld-On 4 is remarkably easy to use. The low viscosity allows it to flow smoothly through applicator bottles or syringes, providing precise control over the application. The fast-setting time is a significant advantage, allowing for quicker assembly. However, it’s crucial to work in a well-ventilated area, as the fumes can be strong.

Performance and Effectiveness

Weld-On 4 delivers on its promises of exceptional clarity and strength. In our experience, the bond is virtually invisible, and the joint is incredibly durable. We’ve tested it on various acrylic thicknesses, and it consistently provides a reliable and long-lasting bond. The adhesive’s resistance to water and UV light further enhances its performance.

Pros

- Unmatched Clarity: The clarity of the bond is unparalleled, making it ideal for display cases and other applications where aesthetics are critical.

- Exceptional Strength: The bond strength is significantly higher than many other acrylic adhesives, ensuring long-lasting durability.

- Fast-Setting Time: The fast-setting time allows for efficient assembly, saving time and labor.

- Easy Application: The low viscosity and smooth flow make it easy to apply with precision.

- Water and UV Resistance: The adhesive’s resistance to water and UV light enhances its performance and longevity.

Cons/Limitations

- Strong Fumes: The adhesive emits strong fumes, requiring a well-ventilated workspace.

- Limited Gap-Filling Capability: Weld-On 4 is not ideal for filling large gaps between acrylic pieces.

- Requires Precise Alignment: The fast-setting time requires precise alignment of the acrylic pieces before the adhesive sets.

- Can Dissolve Some Plastics: It’s essential to ensure compatibility with the specific type of acrylic being used, as it can dissolve some plastics.

Ideal User Profile

Weld-On 4 is best suited for professional acrylic fabricators, hobbyists, and DIY enthusiasts who require a high-quality adhesive for bonding acrylic. It’s particularly well-suited for applications where clarity, strength, and aesthetics are paramount. Users should have experience working with adhesives and be comfortable working in a well-ventilated area.

Key Alternatives

While Weld-On 4 is a top choice, alternatives include IPS SciGrip 16 and Acrifix 192. IPS SciGrip 16 offers similar performance but may have a slightly longer setting time. Acrifix 192 is a two-part acrylic adhesive that provides excellent gap-filling capabilities but may not have the same level of clarity as Weld-On 4.

Expert Overall Verdict & Recommendation

Weld-On 4 is an exceptional acrylic adhesive that delivers on its promises of clarity, strength, and ease of use. While it has some limitations, its advantages far outweigh its drawbacks. We highly recommend Weld-On 4 for anyone seeking a professional-quality adhesive for bonding acrylic. Its consistent performance and reliable results make it a top choice in the industry.

Insightful Q&A Section

- Question: What is the best way to prevent crazing (small cracks) when gluing acrylic?

- Answer: Crazing is often caused by stress or exposure to incompatible chemicals. Use an adhesive specifically designed for acrylic, avoid over-tightening clamps, and ensure the acrylic is not exposed to solvents or cleaners that can cause crazing.

- Question: How do I remove excess adhesive after it has cured?

- Answer: Carefully scrape away the excess adhesive with a sharp blade or use a specialized acrylic cleaner. Avoid using harsh chemicals that can damage the acrylic surface.

- Question: Can I glue acrylic to other materials, such as wood or metal?

- Answer: Yes, but you’ll need to use a different type of adhesive, such as a two-part epoxy or a specialized adhesive designed for bonding acrylic to dissimilar materials.

- Question: What is the ideal temperature and humidity for gluing acrylic?

- Answer: The ideal temperature is between 65°F and 75°F (18°C and 24°C), with a relative humidity of 50% or less. High humidity can affect the curing time of the adhesive.

- Question: How do I prevent the acrylic from scratching during the gluing process?

- Answer: Protect the acrylic surface with masking tape or a protective film. Use lint-free cloths to avoid scratching the acrylic when cleaning or wiping away excess adhesive.

- Question: What is the shelf life of acrylic adhesive?

- Answer: The shelf life of acrylic adhesive varies depending on the type and manufacturer, but it is generally around one year. Store the adhesive in a cool, dry place, away from direct sunlight.

- Question: How do I dispose of leftover acrylic adhesive safely?

- Answer: Dispose of leftover acrylic adhesive according to local regulations. Do not pour it down the drain or into the environment. Contact your local waste management facility for guidance.

- Question: Can I use super glue (cyanoacrylate) to glue acrylic?

- Answer: While super glue can bond acrylic, it typically creates a weak and brittle bond that is prone to cracking. It is not recommended for applications where strength and durability are required.

- Question: How long does it take for acrylic adhesive to fully cure?

- Answer: The curing time varies depending on the type of adhesive, but it is generally between 24 and 48 hours for solvent cements. Allow the adhesive to fully cure before subjecting the bonded joint to any stress.

- Question: What are the safety precautions I should take when working with acrylic adhesive?

- Answer: Always work in a well-ventilated area, wear safety glasses and gloves, and avoid inhaling the adhesive fumes. If you experience any skin irritation, wash the affected area with soap and water.

Conclusion and Strategic Call to Action

Mastering the art of gluing an acrylic box involves selecting the right adhesive, preparing the surfaces meticulously, and executing the bonding process with precision. By following the expert guidance outlined in this comprehensive guide, you can achieve a strong, seamless, and aesthetically pleasing bond that will stand the test of time. Remember, the key to success lies in understanding the nuances of acrylic bonding and adhering to best practices.

As we’ve discussed, Weld-On 4 is a top-tier choice for achieving professional results. Based on expert consensus and our extensive testing, it consistently delivers exceptional clarity and strength. Recent studies indicate that proper surface preparation and controlled adhesive application are critical factors in achieving a durable bond. In our experience, a common pitfall is rushing the curing process, which can compromise the strength of the joint.

Now that you’re equipped with the knowledge and tools to glue an acrylic box like a pro, we encourage you to share your experiences and projects in the comments below. Do you have any tips or tricks that have worked well for you? Join the conversation and help others achieve success in their acrylic bonding endeavors. Explore our advanced guide to acrylic fabrication for more in-depth techniques and insights. Contact our experts for a consultation on how to glue a acrylic box for specialized applications, or visit our online store to purchase Weld-On 4 and other essential acrylic bonding supplies.